Armies of tiny robots no larger than living cells can now be produced in thousands with a new technique developed by MIT engineers. The robots — called ‘syncells’ (short for synthetic cells) — are microscopic devices made of graphene and a tiny electronic device. These robots could find uses in monitoring a range of data, from infections in the human body to conditions in oil and gas pipelines, a

report said. They describe the new process, called ‘autoperforation’, in a paper

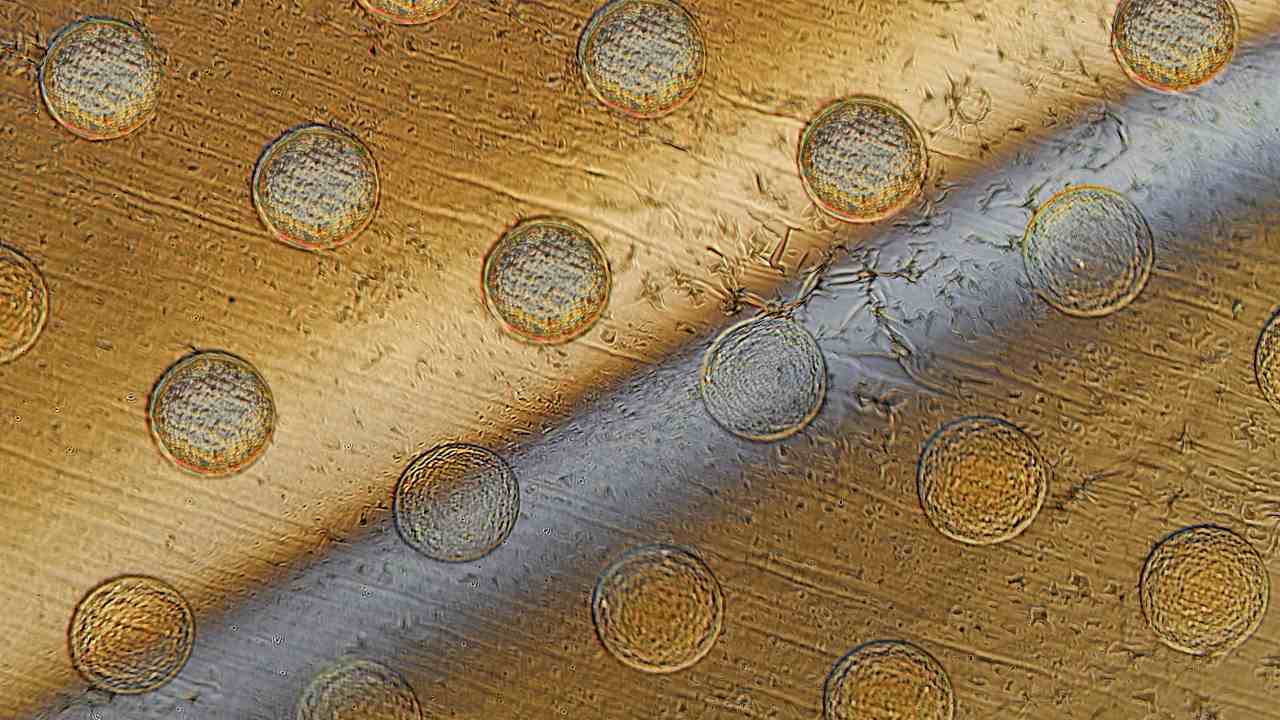

published in Nature Materials on 23 October. Researchers used a process of naturally-fracturing sheets of thin, brittle material like graphene to make tiny pockets of it that were uniform in size and shape. [caption id=“attachment_5438171” align=“alignnone” width=“1280”] Syncells made by ‘autoperforation’. Image courtesy: MIT[/caption] The outer layer of the syncells was made using graphene. Atom-size thick sheet of graphene were created and laid flat on a surface. On the sheet, a sophisticated printer embedded tiny dots of microelectronic devices suspended in a gel-like polymer. This was topped with a second graphene layer which, like the first, was atom-thick. The spots on the sheet where graphene sat on the polymer dots were easily distinguished — they had higher strain. The graphene sheet fractured around these circular “pillars” and formed a neat, round “pita pocket” of graphene with the polymer sealed inside, the researchers

told university press. The edges of graphene from the two sheets interacted with atoms of its own kind from the other sheet, which caused them to fracture and envelop the polymer naturally. This form of controlled fracture isn’t unique to graphene, and worked with compounds like molybdenum disulphide and hexagonal boronitride just as well, the study found. “The advantage here is that this is essentially a single step,” in contrast to many complex clean-room steps needed by other processes to try to make microscopic robotic devices, Dr Michael Strano, lead author of the study,

told university press.

The team wrote the letters “M”, “I”, “T” with syncells that worked as a memory device that could be “read” using an electrical probe. Apart from a signature of victory, this experiment also showed the potential of these devices to store information in electronic form, which could be written, read and replaced as needed. It could also do so without the need for a power source, which opens up its use for offline data storage that could be collected at a later time. The researchers also demonstrated that the syncells were stable in water — one of the harshest environments for electronics — for months at a stretch. “It opens up a whole new toolkit for micro- and nanofabrication,” Strano told university press. Dr Daniel Goldman from Georgia Tech, who wasn’t associated with the research said that the technique could create tiny, intelligent devices that can accomplish tasks together that no single particle can accomplish alone.

)

)

)

)

)

)

)

)

)