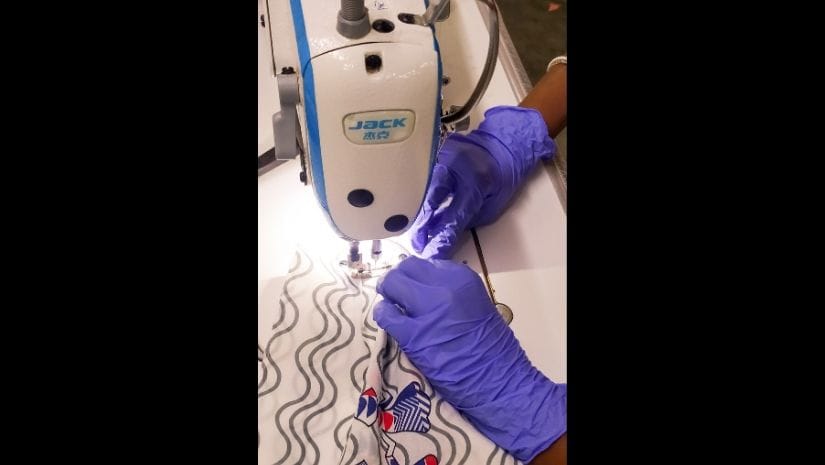

It was a day after the lockdown initiated in light of the coronavirus crisis that Delhi-based designer Pallavi Mohan began producing face masks with filters on the urging of a friend, to supply them to hospital workers. Procuring the necessary permits to operate her factory, Mohan’s team at Not So Serious has since then already produced 25,000 masks that will be distributed among hospital staff and medical professionals. The activity also involves making three-layered printed cotton masks for distribution in areas where they are in short supply. According to government directives, it is now compulsory for every individual to wear a cotton mask (not the N95 masks utilised by healthcare professionals) while stepping out of their homes to buy groceries or essentials from the nearest vendor. With the number of these masks available in the market being nowhere close to their demand, many designers have opened up their factories and begun producing reusable, washable cotton masks in a bid to supply them to slum dwellers, daily wage earners and others who do not have access to this essential commodity. The House of Anita Dongre label recently announced that it will be manufacturing cloth masks in two of its five rural centres employing women who live close to the production facility. The initiative involves 24 women stitching up to 7,000 cloth masks per week for distribution to NGOs and hospital staff. The fabric used by Dongre to manufacture these masks is the stock that the designer had purchased for her labels AND, Global Desi and Anita Dongre. The team will also be manufacturing masks for the local hospital in Palgarh for doctors and nurses. [caption id=“attachment_8299781” align=“alignnone” width=“825”]  A woman stitching a face mask at Anita Dongre’s facility in Charoti.[/caption] Of the initiative, the designer said, “As long as people need masks they will be produced and distributed.” For her part, Mohan, who has nearly 25 tailors, each one working to make 350 masks every day, this is simply the right thing to do given the need of the hour and the resources at her disposal. The masks are being made using the cotton fabric in stock which is washed and sanitised using a machine which essentially ‘looks like an oven’ and ‘sanitises the masks before they are packed’. “I’m selling them at my cost price to people who can afford it, and the funds that I get, I use them to give [masks] to doctors and anybody who doesn’t have access to them,” she says. However, there are restrictions as to the number of masks that can be produced given the constraints on transportation. “Even if I make them in large numbers,” she notes, “how do I get them to the people right now?” [caption id=“attachment_8299801” align=“alignnone” width=“825”]  Production of face masks at Anita Dongre’s facility in Charoti.[/caption] So also, a number of precautions have to taken within the manufacturing unit itself to ensure the safety of the staff. It is completely different from a regular work day, Mohan observes. Working in the factory involves employees maintaining the prescribed distance between two machines, a sanitising team that cleans the machines every few hours and a nurse on hand, as a precautionary measure. “Anything that comes in — even a piece of paper — is sanitised before it’s brought in,” Mohan adds. Fashion labels including Limerick and Karleo are among those who have been contributing in making masks along with designers such as Nitya Bajaj, who used the excess fabric from her Spring Summer 2020 collection ‘Daisy’ to make washable, reusable masks for distribution among street children, hospital staff and the needy. The scraps of fabric were cut and quilted and then lined with silk and sterilised before packaging. Bajaj’s team made 1,300 masks prior to the lockdown and the designer has also actively engaged in sharing DIY tips on social media in collaboration with Delhi Times on how to make washable masks at home using readily available materials such as cotton socks.

With her initiative Maskaba, Masaba Gupta has also joined the list of designers who have been using the cloth that is available in their factories to produce and supply masks to coronavirus affected areas. Masaba’s team comprises three workers who live at the facility and make the masks from fabric that was meant for producing garments. In an Instagram post, Gupta wrote, “We have started the production of non-surgical masks for donation at a production facility keeping all hygiene and safety standards in mind. These masks are washable and reusable.”

Using cotton, khadi, ikat and other leftover material from his previous collections, designer Manish Tripathi has also created cotton masks with the help of his employees who have stayed back during the lockdown. The masks are being distributed among people who cannot afford them or do not have access to a clean cloth or scarf that can be wrapped on their faces.

In this tough times,as responsible citizen its our duty to stay safe & keep others also protected. Will continue to distribute these handmade cotton reusable masks to the ones who cant afford it. My prayers for all. @PMOIndia #FightCovid19 pic.twitter.com/4gPUYapWKH

— Manish Tripathi (@ManishantarDESI) April 13, 2020

Yet another designer to join this movement is Mumbai-based Neeta Lulla who started making washable face masks a few days before the lockdown came into effect in the last week of March. Made of cotton linen and thick cotton jersey, Lulla’s team produced 800 masks and distributed them among vegetables vendors, taxi drivers and others in the city. “One feels very helpless in a situation like this,” says designer Ritu Kumar, “not being able to get too much in touch with all the workers,” but in keeping with the idea of contributing in a more effective and tangible manner rather than sending money to an organisation, Kumar’s team of 30 people is also engaged in producing 2,000 masks a day to achieve their target of delivering 50,000 pieces to those in affected areas. [caption id=“attachment_8299831” align=“alignnone” width=“825”]  Masks manufactured at Ritu Kumar’s Gurgaon facility.[/caption] Kumar says that the idea behind project was simply to consider, “What can we do which is going to be both practical and required?” Ensuring safety measures such as adequate distancing between two machines and sanitising the entire unit, her team at its Gurgaon facility thus began the production of the non-surgical masks and have already supplied as many as 15,000 pieces to affected communities in the slums of Haryana. [caption id=“attachment_8299841” align=“alignnone” width=“825”]  Ritu Kumar’s production facility aims to supply as many as 50000 masks to those in affected areas.[/caption] While the market requirement for these masks in the future is unclear, Kumar says, “These masks are not designer masks. They are not being designed to sell, they are being designed to help at the moment.”

)

)

)

)

)

)

)

)

)