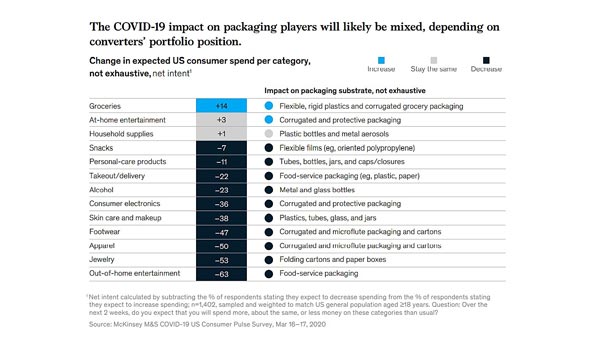

Today, the scope of leveraging the Industrial Internet of Things (IIoT) is tremendous. It helps connect and integrate machines and facilities with complex IT systems, enabling efficiencies in product development and manufacturing, and in meeting individual customer requirements. IIoT thus helps achieve a fully connected, transparent, automated, and intelligent manufacturing setup to improve and optimize industrial processes. The plastics industry faces several challenges including lack of real-time visibility of operational parameters, accurate measurement and predictive analytics. In addition, it is not easy to draw conclusions from data collection; and often, manufacturing firms cannot implement recommendations swiftly. Leveraging IIoT in the plastics industry would help solve problems such as insufficient equipment effectiveness and downtime. While the COVID-19 pandemic has drastically affected the global market – including the plastics industry, experts predict its output to recover in the post-pandemic recovery stage. Growth prospects While several reasons account for this possible recovery, one of the chief reasons this sector’s growing is increasing consumer demand due to plastics being understood to be “safe” and “essential” in responding to COVID-19. In the public discourse, plastic is considered resistant to COVID-19 transmission. Which is why it is not just masks, gloves and other PPE that are made from plastics; even delivery cartons, beverage bottles and other single-use packaging that most people have used through the pandemic (and beyond) that is leading to an ever-increasing demand for plastic. In this regard, a McKinsey global report based on a US consumer survey, expects the impact of the crisis on the packaging industry to be mixed. The report claims that demand will rise sharply for packaging for groceries, healthcare products, and e-commerce transportation. At the same time, demand for industrial, luxury, and some B2B-transport packaging could decline. The impact on packaging players would depend on their portfolios and exposures to different regions, end uses for packaging and substrates.

One of the other issues that the plastics industry has been confronting on a wider scale, is that of ecologically sustainable manufacturing and sustainable disposal of plastic waste. The industry has risen to the challenge and tackled several of these – especially with regard to sustainable packaging and product disposal. Many countries have stringent guidelines on the usage of single-use plastics. Thus, there is a need for constant innovation to meet the industry’s evolving demands. This is where IIoT and ExxonMobil’s expertise can be leveraged for further optimization and achieving greater efficiencies. The Mobil Legacy and Energy Innovation In 1866, Hiram Bond Everest established the Vacuum Oil Company to promote petroleum-based lubricants and patented the vacuum distillation process. It eventually was an industry leader in almost all energy and chemical manufacturing businesses and became part of what is now ExxonMobil. For more than 135 years, ExxonMobil has harnessed new technologies to better provide energy for the world. That effort continues with a growing focus on digital technology. Today, the company uses high-performance computing, advanced data analytics, and increased connectivity to transform how the organization works at every level of its operations and enhances the way it interacts with customers. From the Internet of Things (IoT) projects that make refineries more efficient, to state-of-the art digital tools that help support production and detect methane emissions from operations, ExxonMobil is leveraging global scale to turn data into unique insights that drive improved reliability and performance. A digital mindset has been adopted across the company, enabling greater agility, speed and value without sacrificing discipline and rigor. The company has also launched cutting-edge collaborations with Microsoft, IBM and Intel to push into new areas – like quantum computing – to help tackle modern energy challenges. Leadership in Plastics and a New Age in Technology As one of the world’s largest publicly traded energy providers and chemical manufacturers, ExxonMobil develops and applies next-generation technologies to help safely and responsibly meet the increasing global demand for energy and high-quality chemical products. Mobil™ industrial lubricants have since long assisted plastic manufacturers in creating equipment that produces high-quality parts and products for every unit, whether made in long runs or short custom campaigns. Our complete line of hydraulic oils is formulated to assist plastic manufacturers in ensuring their operations are running efficiently. Similarly, Mobil DTE™ 20 Ultra Series hydraulic oils have long been recognized for their keep-clean performance and durability while helping customers achieve long oil life. Along with a complete line of hydraulic oils, gear and compressor oils, fluids, and greases, Mobil also provides a wide array of technical services under its Mobil ServSM umbrella such as heat transfer system and auxiliary equipment, catering to industries such as plastic, pulp and paper, coal, gas turbines, among others. Among these services, Mobil ServSM Real Time is a next-gen condition monitoring tool that transforms oil maintenance with live information and actionable insights through IIoT technology. It is a vital tool that monitors the lubricant health in real-time and sends instant real-time alerts. Therefore,

Mobil ServSM Real Time

is a much-needed asset to help plastic manufacturers make swift decisions while safeguarding their business efficiency. Additionally, it helps them save on oil consumption and the total cost of operation, enables early detection, immediate reporting, and much more. The latest offering from ExxonMobil –

Mobil ServSM IIoT Insights

, can boost plastic manufacturing efficiency with AI insights and automated data collection. To amplify the efficiency of machines, Mobil Serv IIoT Insights can turn raw data into meaningful recommendations. It helps plastic manufacturers gain data-driven insights into their machines and make profitable decisions for their business. Guided by AI-enabled trend analysis, manufacturers also get to implement a swift course of action and get real-time access to data and analytics, among other additional benefits. Mobil Serv’s IIoT Insights Bolstering Plastic Production and Efficiency The ability of Mobil Serv’s IIoT Insights to convert raw production data into actionable insights and its AI/ML-powered functionality helps the manufacturing team receive customized alerts, optimize energy consumption, measure equipment effectiveness, and enable trend monitoring, among others. IIoT Insights makes minor hardware integrations and configurations seamless to enable machines for automatic data capturing. Control panel data is interfaced into the Mobil Serv IIoT solution through a gateway installed at the site. With the Mobil Serv IIoT solution, site managers can receive an aggregated data view for their management reporting, e.g., daily production details, machine run time, downtime details, etc. Additionally, the solution helps top business executives get direct access to high-level business metrics like machine overall equipment effectiveness (OEE), energy consumption, and other production details. It also helps them gain insights into drivers of underperformance through high-level metrics while also identifying the opportunities for increasing efficiencies. Mobil ServSM IIoT Insights is thus the much-needed cloud-based solution for the plastics industry to turn insights into action and achieve improved efficiency and overall productivity.

Get in touch

with us to help you upgrade and boost productivity the AI way! This is a Partnered post written by Mr. Ankush Khanna, Director- Commercial Brand Marketing (South Asia Pacific)

One of the other issues that the plastics industry has been confronting on a wider scale, is that of ecologically sustainable manufacturing and sustainable disposal of plastic waste. The industry has risen to the challenge and tackled several of these – especially with regard to sustainable packaging and product disposal. Many countries have stringent guidelines on the usage of single-use plastics. Thus, there is a need for constant innovation to meet the industry’s evolving demands. This is where IIoT and ExxonMobil’s expertise can be leveraged for further optimization and achieving greater efficiencies. The Mobil Legacy and Energy Innovation In 1866, Hiram Bond Everest established the Vacuum Oil Company to promote petroleum-based lubricants and patented the vacuum distillation process. It eventually was an industry leader in almost all energy and chemical manufacturing businesses and became part of what is now ExxonMobil. For more than 135 years, ExxonMobil has harnessed new technologies to better provide energy for the world. That effort continues with a growing focus on digital technology. Today, the company uses high-performance computing, advanced data analytics, and increased connectivity to transform how the organization works at every level of its operations and enhances the way it interacts with customers. From the Internet of Things (IoT) projects that make refineries more efficient, to state-of-the art digital tools that help support production and detect methane emissions from operations, ExxonMobil is leveraging global scale to turn data into unique insights that drive improved reliability and performance. A digital mindset has been adopted across the company, enabling greater agility, speed and value without sacrificing discipline and rigor. The company has also launched cutting-edge collaborations with Microsoft, IBM and Intel to push into new areas – like quantum computing – to help tackle modern energy challenges. Leadership in Plastics and a New Age in Technology As one of the world’s largest publicly traded energy providers and chemical manufacturers, ExxonMobil develops and applies next-generation technologies to help safely and responsibly meet the increasing global demand for energy and high-quality chemical products. Mobil™ industrial lubricants have since long assisted plastic manufacturers in creating equipment that produces high-quality parts and products for every unit, whether made in long runs or short custom campaigns. Our complete line of hydraulic oils is formulated to assist plastic manufacturers in ensuring their operations are running efficiently. Similarly, Mobil DTE™ 20 Ultra Series hydraulic oils have long been recognized for their keep-clean performance and durability while helping customers achieve long oil life. Along with a complete line of hydraulic oils, gear and compressor oils, fluids, and greases, Mobil also provides a wide array of technical services under its Mobil ServSM umbrella such as heat transfer system and auxiliary equipment, catering to industries such as plastic, pulp and paper, coal, gas turbines, among others. Among these services, Mobil ServSM Real Time is a next-gen condition monitoring tool that transforms oil maintenance with live information and actionable insights through IIoT technology. It is a vital tool that monitors the lubricant health in real-time and sends instant real-time alerts. Therefore,

Mobil ServSM Real Time

is a much-needed asset to help plastic manufacturers make swift decisions while safeguarding their business efficiency. Additionally, it helps them save on oil consumption and the total cost of operation, enables early detection, immediate reporting, and much more. The latest offering from ExxonMobil –

Mobil ServSM IIoT Insights

, can boost plastic manufacturing efficiency with AI insights and automated data collection. To amplify the efficiency of machines, Mobil Serv IIoT Insights can turn raw data into meaningful recommendations. It helps plastic manufacturers gain data-driven insights into their machines and make profitable decisions for their business. Guided by AI-enabled trend analysis, manufacturers also get to implement a swift course of action and get real-time access to data and analytics, among other additional benefits. Mobil Serv’s IIoT Insights Bolstering Plastic Production and Efficiency The ability of Mobil Serv’s IIoT Insights to convert raw production data into actionable insights and its AI/ML-powered functionality helps the manufacturing team receive customized alerts, optimize energy consumption, measure equipment effectiveness, and enable trend monitoring, among others. IIoT Insights makes minor hardware integrations and configurations seamless to enable machines for automatic data capturing. Control panel data is interfaced into the Mobil Serv IIoT solution through a gateway installed at the site. With the Mobil Serv IIoT solution, site managers can receive an aggregated data view for their management reporting, e.g., daily production details, machine run time, downtime details, etc. Additionally, the solution helps top business executives get direct access to high-level business metrics like machine overall equipment effectiveness (OEE), energy consumption, and other production details. It also helps them gain insights into drivers of underperformance through high-level metrics while also identifying the opportunities for increasing efficiencies. Mobil ServSM IIoT Insights is thus the much-needed cloud-based solution for the plastics industry to turn insights into action and achieve improved efficiency and overall productivity.

Get in touch

with us to help you upgrade and boost productivity the AI way! This is a Partnered post written by Mr. Ankush Khanna, Director- Commercial Brand Marketing (South Asia Pacific)

How ExxonMobil Is Leveraging IIoT Solutions to Optimize Plastic Manufacturing

studio18

• September 8, 2021, 15:15:58 IST

The plastics industry faces several challenges including lack of real-time visibility of operational parameters, accurate measurement and predictive analytics. In addition, it is not easy to draw conclusions from data collection; and often, manufacturing firms cannot implement recommendations swiftly.

Advertisement

)

End of Article